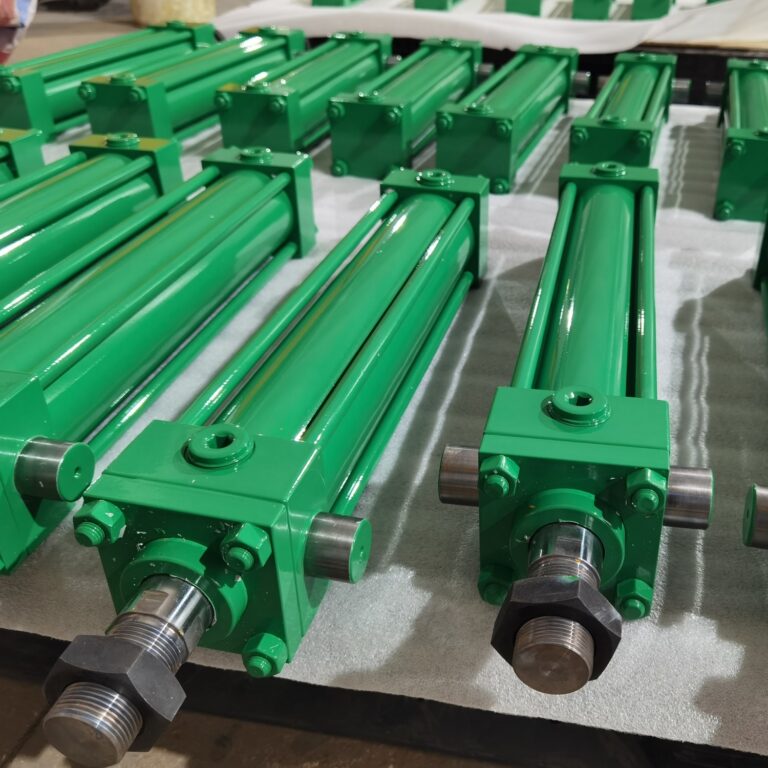

Hydraulic cylinder for vulcanizing machine

Background: We received a new order of 223 sets hydraulic cylinders for Vulcanizing Machine

- The live molds cylinder size: 63/35-S305

- The mold opening and closing size: 160/90-S1980

- The loading and unloading cylinder size: 63/35-S1500 and 63/35-S1650

Hydraulic Cylinder for Vulcanizing Machines

The hydraulic cylinder for vulcanizing machines is a crucial component designed to provide the force and precision necessary for various operations during the vulcanization process in rubber manufacturing. This cylinder plays a key role in ensuring effective molding, curing, and material handling, contributing significantly to high-quality production and operational efficiency.

Key Features:

High Pressure Capacity:

Engineered to generate substantial hydraulic force, this cylinder is essential for compressing molds and maintaining the pressures required for effective vulcanization.Rugged Construction:

Manufactured from high-strength materials, it is built to withstand the extreme temperatures and harsh conditions typical in vulcanizing operations, ensuring long-lasting durability and reliability.Smooth Operation:

The advanced hydraulic design ensures smooth, controlled movements, which enhances the efficiency of the vulcanization cycle and reduces overall cycle times.Versatile Applications:

Suitable for a wide range of vulcanizing machines, this hydraulic cylinder supports various rubber manufacturing processes, including tire production, gaskets, and oil seals.Low Maintenance Requirements:

Designed to minimize wear and tear, this hydraulic cylinder requires less maintenance, helping to reduce downtime and increase overall productivity.

Hydraulic Cylinder for Tire Loading and Unloading in Vulcanizing Machines

The Hydraulic Tire Loading and Unloading Cylinder is a vital component in the vulcanizing process, designed to facilitate the efficient handling of tires during production. This cylinder generates the necessary force to smoothly lift and position tires for loading into molds, as well as safely unload them once the curing process is complete.

Constructed from high-strength materials, the hydraulic cylinder is engineered to endure the demanding conditions and high pressures typically encountered in vulcanizing operations, ensuring both durability and reliability throughout its service life.

The cylinder’s smooth hydraulic action provides precise control, allowing for quick adjustments that enhance operational efficiency. This contributes to the overall safety and effectiveness of the tire manufacturing process.

As an essential element in the operation of vulcanizing machines, the hydraulic loading and unloading cylinder optimizes machine functionality and plays a significant role in the production of high-quality tires. Its reliable performance helps streamline the tire manufacturing process, making it indispensable for efficient production.

Hydraulic Cylinder for Mold Opening and Closing in Vulcanizing Machines

The mold opening and closing hydraulic cylinder for vulcanizing machines is a crucial component that ensures the precise operation of molds during the vulcanization process. This cylinder generates the force necessary to smoothly separate and secure the mold halves, guaranteeing accurate alignment and efficient curing of the rubber material.

Constructed from high-strength materials, the cylinder is built to withstand the extreme pressures and conditions typical in vulcanizing operations, ensuring long-lasting durability and reliable performance. Its robust design ensures it can handle the demanding environment of the vulcanization process without compromising functionality.

The hydraulic action of the cylinder provides controlled, smooth movements, which improves both the safety and efficiency of the production process. By enabling precise mold control, it helps optimize the overall vulcanization cycle, resulting in consistent product quality.

This hydraulic cylinder is essential for optimizing the functionality of vulcanizing machines, significantly enhancing the quality and consistency of the rubber products being produced.

Hydraulic Cylinder for Live Molds in Vulcanizing Machines

The Live Molds Hydraulic Cylinder for vulcanizing machines is a vital hydraulic component designed to provide precise movement and control for live molds during the vulcanization process. This cylinder generates the necessary force to open, close, and adjust mold positions, ensuring optimal contact between the rubber material and the mold surfaces for effective and consistent curing.

Constructed from high-strength materials, the hydraulic cylinder is built to withstand the harsh conditions and high pressures typical of vulcanizing operations, guaranteeing durability and long-term reliability. Its robust design ensures dependable performance even under demanding working conditions.

The smooth hydraulic action facilitates quick and accurate adjustments, improving operational efficiency and overall productivity in rubber manufacturing. By enabling precise control of mold movement, this hydraulic cylinder helps streamline the vulcanization process, contributing to the production of high-quality rubber products.

This hydraulic cylinder is essential for optimizing the performance of vulcanizing machines, significantly enhancing the quality and consistency of the rubber products produced.